Our Estimating module is designed for the user to enter a rebar takeoff and directly price it without any extra data entry.

This module takes an estimate entered in the Estimating module and forms a sales proposal for bidding a project.

This module takes estimates that are awarded and converts them into contracts. This effectively links the estimate with the contract, allowing later modules such as Job Costing to compare estimated vs. actual quantities & revenue.

This module is designed as a complete application that integrates every aspect of a fabrication plant (barlist entry/import from detailing, scheduling, tag and barlist printing, load dispatch and dashboard, and shipping).

The Field Placing module is designed as a tool to manage field operations. It is used to schedule ironworkers, track hours worked on various job segments, compare estimate vs actual placing productivity, and produce certified payroll reporting/exports.

The Field App gives jobsite foremen the ability to track their jobs and easily report timecard and placing activity.

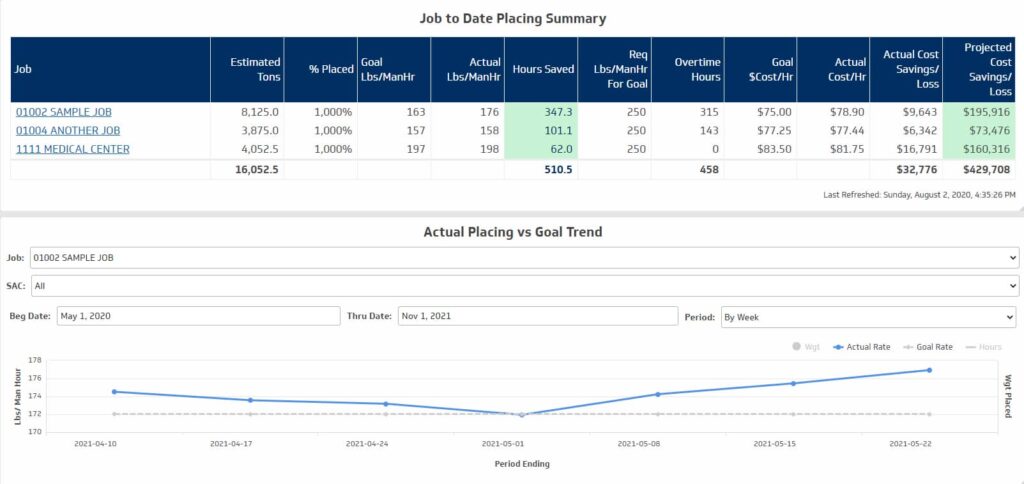

The Field KPI quickly summarizes the estimated vs. actual placing activity per job and shows projected cost savings and overages.

The Contract Billing module calculates and generates invoices for all contracts and retail orders entered/produced in the Production module.

The Accounting interface module is designed to send the data from the Soule system into your company’s accounting software.

This module calculates the balance remaining to ship for each contract job and allows project managers to schedule the backlog out into future months. This enables your company to project inventory requirements down to the part (bar size/grade/coating) level by fab shop and month.

The Job Costing module combines all the information stored for each awarded estimate (revised with approved change orders), the actual shipments and placing activity during the accounting period, and the general ledger costs to produce an accurate profit/loss by job.

The Reporting module brings the entire collection of more than 180+ reports available in the system into one place organized by category with a brief description and sample of each report.

The Drawing Submittal module helps track all of the detailer’s drawings (including revisions and submittals) and their time spent on each drawing.

The Detailing module helps a detailer take a set of plans for a job and create a detailed bar list and placing sheet, track pour schedules, log RFIs, and create potential change order alerts.

The Optimization module calculates the most efficient and cost-effective method to fabricate a selected group of orders.

The Fab KPI quickly summarizes the weekly schedule for fabrication and shows actual man hours per ton vs goal for each of your plants.

The Freight Tracking module tracks loads from your fab shop to the job site using the driver's cell phone (your employee or outside vendors) and provides load ETA and status updates.

The Mill Certs module allows for tracking original mill heats (and paperwork) from inventory through fabrication for each project and gives the ability to generate a single packet of PDFs for each shipment.

The Customer Document Download system allows the customers to get a link on their invoices to download all of the paperwork related to their delivery/load/project (or retail) billing.

The Customer Portal allows you to accept online orders from your customers and gives them access to download their own paperwork from your website.

The Inventory module provides an easy way to track and manage both your bundle stock inventory and non-rebar items from the generation of purchase orders through the relief of inventory and reporting on its usage.

The Bar Code Scanning system is the most advanced scanning solution available in the rebar industry. Scanners work without special app store downloads and connect via WiFi or cell data. They can work offline and resend stored scans when back online. The office can easily view real-time fabrication, loading, and delivery scans from dashboards.

Our Estimating module is designed for the user to enter a rebar takeoff and directly price it without any extra data entry.

This module takes an estimate entered in the Estimating Module and forms a sales proposal for bidding a project.

This module takes estimates that are awarded and converts them into contracts. This effectively links the estimate with the contract, allowing later modules such as Job Costing to compare estimated vs. actual quantities & revenue.

This module is designed as a complete application that integrates every aspect of a fabrication plant (barlist entry/import from detailing, scheduling, tag and barlist printing, load dispatch and dashboard, and shipping).

The Contract Billing module calculates and generates invoices for all contracts and retail orders entered/produced in the Production module.

The Accounting interface module is designed to send the data from the Soule system into your company’s accounting software.

This module calculates the balance remaining to ship for each contract job and allows project managers to schedule the backlog out into future months. This enables your company to project inventory requirements down to the part (bar size/grade/coating) level by fab shop and month.

The Job Costing module combines all the information stored for each awarded estimate (revised with approved change orders), the actual shipments and placing activity during the accounting period, and the general ledger costs to produce an accurate profit/loss by job.

The Reporting module brings the entire collection of more than 180+ reports available in the system into one place organized by category with a brief description and sample of each report.

The Drawing Submittal module helps track all of the detailer’s drawings (including revisions and submittals) and their time spent on each drawing.

The Detailing module helps a detailer take a set of plans for a job and create a detailed bar list and placing sheet, track pour schedules, log RFIs, and create potential change order alerts.

The Optimization module calculates the most efficient and cost-effective method to fabricate a selected group of orders.

The Fab KPI quickly summarizes the weekly schedule for fabrication and shows actual man-hours per ton vs goal for each of your plants.

The Freight Tracking module tracks loads from your fab shop to the job site using the driver's cell phone (your employee or outside vendors) and provides load ETA and status updates.

The Mill Certs module allows for tracking original mill heats (and paperwork) from inventory through fabrication for each project and gives the ability to generate a single packet of PDFs for each shipment.

The Customer Document Download system allows the customers to get a link on their invoices to download all of the paperwork related to their delivery/load/project (or retail) billing.

The Customer Portal allows you to accept online orders from your customers and gives them access to download their own paperwork from your website.

The Inventory module provides an easy way to track and manage both your bundle stock inventory and non-rebar items from the generation of purchase orders through the relief of inventory and reporting on its usage.

The Bar Code Scanning system is the most advanced scanning solution available in the rebar industry. Scanners work without special app store downloads and connect via WiFi or cell data. They can work offline and resend stored scans when back online. The office can easily view real-time fabrication, loading, and delivery scans from dashboards.

Our Estimating module is designed for the user to enter a rebar takeoff and directly price it without any extra data entry.

This module takes an estimate entered in the Estimating Module and forms a sales proposal for bidding a project.

This module takes estimates that are awarded and converts them into contracts. This effectively links the estimate with the contract, allowing later modules such as Job Costing to compare estimated vs. actual quantities & revenue.

This module is designed as a complete application that integrates every aspect of a fabrication plant (barlist entry/import from detailing, scheduling, tag and barlist printing, load dispatch and dashboard, and shipping).

The Field Placing module is designed as a tool to manage field operations. It is used to schedule ironworkers, track hours worked on various job segments, compare estimate vs actual placing productivity, and produce certified payroll reporting/exports.

The Field App gives jobsite foremen the ability to track their jobs and easily report timecard and placing activity.

The Field KPI quickly summarizes the estimated vs. actual placing activity per job and shows projected cost savings and overages.

The Contract Billing module calculates and generates invoices for all contracts and retail orders entered/produced in the Production module.

The Accounting interface module is designed to send the data from the Soule system into your company’s accounting software.

This module calculates the balance remaining to ship for each contract job and allows project managers to schedule the backlog out into future months. This enables your company to project inventory requirements down to the part (bar size/grade/coating) level by fab shop and month.

The Job Costing module combines all the information stored for each awarded estimate (revised with approved change orders), the actual shipments and placing activity during the accounting period, and the general ledger costs to produce an accurate profit/loss by job.

The Reporting module brings the entire collection of more than 180+ reports available in the system into one place organized by category with a brief description and sample of each report.

The Drawing Submittal module helps track all of the detailer’s drawings (including revisions and submittals) and their time spent on each drawing.

TThe Detailing module helps a detailer take a set of plans for a job and create a detailed bar list and placing sheet, track pour schedules, log RFIs, and create potential change order alerts.

Our Estimating module is designed for the user to enter a rebar takeoff and directly price it without any extra data entry.

Key Features

This module takes an estimate entered in the Estimating module and forms a sales proposal for bidding a project.

Key Features

This module takes estimates that are awarded and converts them into contracts. This effectively links the estimate with the contract, allowing later modules such as Job Costing to compare estimated vs. actual quantities & revenue.

Key Features

This module is designed as a complete application that integrates every aspect of a fabrication plant (barlist entry/import from detailing, scheduling, tag and barlist printing, load dispatch and dashboard, and shipping).

Key Features

The Field Placing module is designed as a tool to manage field operations. It is used to schedule ironworkers, track hours worked on various job segments, compare estimate vs actual placing productivity, and produce certified payroll reporting/exports.

Key Features

The Field App gives job site foremen the ability to track their jobs and easily report timecard and placing activity.

Key Features

The Field KPI quickly summarizes the estimated vs. actual placing activity per job and shows projected cost savings and overages.

Key Features

The Contract Billing module calculates and generates invoices for all contracts and retail orders entered/produced in the Production module.

Key Features

The Accounting interface module is designed to send the data from the Soule system into your company’s accounting software.

Key Features

This module calculates the balance remaining to ship for each contract job and allows project managers to schedule the backlog out into future months. This enables your company to project inventory requirements down to the part (bar size/grade/coating) level by fab shop and month.

Key Features

The Job Costing module combines all the information stored for each awarded estimate (revised with approved change orders), the actual shipments and placing activity during the accounting period, and the general ledger costs to produce an accurate profit/loss by job.

Key Features

The Reporting module brings the entire collection of more than 180+ reports available in the system into one place organized by category with a brief description and sample of each report.

Key Features

The Detailing module helps a detailer take a set of plans for a job and create a detailed bar list and placing sheet, track pour schedules, log RFIs, and create potential change order alerts.

Key Features

The Optimization module calculates the most efficient and cost-effective method to fabricate a selected group of orders.

Key Features

The Fab KPI quickly summarizes the weekly schedule for fabrication and shows actual man-hours per ton vs goal for each of your plants.

Key Features

The Freight Tracking module tracks loads from your fab shop to the job site using the driver’s cell phone (your employee or outside vendors) and provides load ETA and status updates.

Key Features

The Mill Certs module allows for tracking original mill heats (and paperwork) from inventory through fabrication for each project and gives the ability to generate a single packet of PDFs for each shipment.

Key Features

The Customer Document Download system allows the customers to get a link on their invoices to download all of the paperwork related to their delivery/load/project (or retail) billing.

Key Features

The Customer Portal allows you to accept online orders from your customers and gives them access to download their own paperwork from your website.

Key Features

The Inventory module provides an easy way to track and manage both your bundle stock inventory and non-rebar items from the generation of purchase orders through the relief of inventory and reporting on its usage.

Key Features

The Bar Code Scanning system is the most advanced scanning solution available in the rebar industry. Scanners work without special app store downloads and connect via WiFi or cell data. They can work offline and resend stored scans when back online. The office can easily view real-time fabrication, loading, and delivery scans from dashboards.

The Drawing Submittal module helps track all of the detailer’s drawings (including revisions and submittals) and their time spent on each drawing.

Key Features